The Product-Process Matrix

Using the Right Process for the Volume of Work You're Doing

© iStockphoto

jcarillet

When you're feeling overloaded, organize your processes for greater efficiency.

You're up against a deadline to get 500 important letters in the mail to your customers.

Which of these approaches do you think would be most efficient?

Scenario A: you assemble each letter one by one. You fold each piece of paper, put it in the envelope, address it, and stamp it.

Scenario B: you work on each task in batches. First, you fold the letters. Then you stuff them in envelopes. Then you address each envelope. And finally, you stamp them.

Whilst it's probably more boring, Scenario B is almost certainly more efficient because you can have the one or two items you need for that single task within easy reach, and you don't waste time switching between tasks.

But in other situations when the same set of tasks need to be carried out multiple times – whether you're dealing with product manufacture, administrative tasks or other types of work – it isn't always obvious how best to organize things.

This is where a tool like the Product-Process Matrix can help. In this article, we'll explain exactly what it is – and how it can help you to decide how to organize processes most efficiently. The tool is particularly useful when you’re introducing or making changes to the volumes of work or product that you need to process.

Understanding the Tool

The Product-Process Matrix was first introduced by Robert Hayes and Steven Wheelwright in the Harvard Business Review in 1979.

It helps organizations identify the type of production approach they should use for a product, based on the volumes of the product being produced, and the amount of customization it needs.

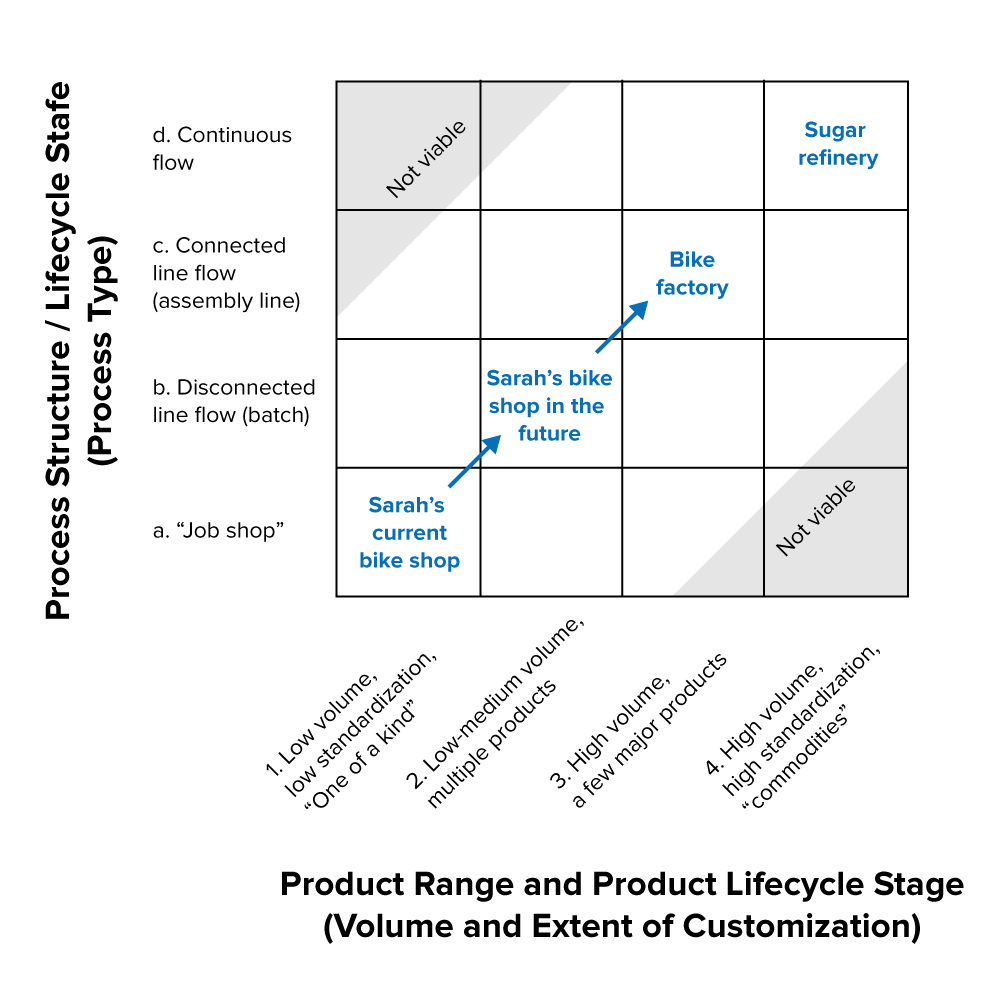

The matches between products and processes are shown in figure 1 below. (This diagram shows an example that we'll refer to later in this article.)

Reprinted by permission of Harvard Business Review. From "Link Manufacturing Process and Product Life Cycles" by Robert H. Hayes and Steven C. Wheelwright, January 1979. Copyright © 1979 by the Harvard Business School Publishing Corporation; all rights reserved.

A Product-Process Matrix Example

Here's a quick example to illustrate how the matrix could help make production more efficient.

Sarah has just opened her first small bicycle shop. All of her bikes are custom designed and built for clients, which is a very lengthy and expensive process. Sarah's business is in the 1a square on the matrix: she makes and sells one bike at a time, operating a low volume job shop.

Sarah's products are very well made, and business starts to improve as more customers place orders for her custom bikes. But Sarah doesn't change her process. She continues to build and sell one bike at a time, and her reputation suffers because there's such a long waiting list.

This means that she's moved to the 3a square. She still builds bikes as if there's a low-volume demand – although, in reality, she now has a high-volume business.

If Sarah doesn't change her process, she might ultimately go out of business, or at least lose customers who don't want to wait for a bike. However, if she looks at the Product-Process Matrix, she'll realize that she needs to hire staff and set up an assembly line to handle the higher volume of orders. Based on her increasing demand, she really needs to be in the 3c square.

The Product-Process Matrix in Detail

Although the Product-Process Matrix was originally created with manufacturing in mind, we can use this tool to help make our own tasks and projects run more efficiently. Let's look at the key squares in greater detail, and then discuss how you can apply the Product-Process Matrix in your own life...

Access the Full Article

This article is only available in full within the Mind Tools Club.

Learn More and Join TodayAlready a Club member? Log in to finish this article.